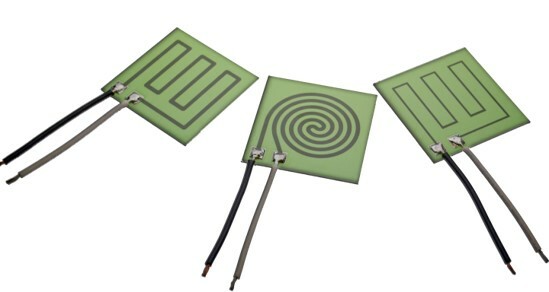

Custom Thick Film Heaters

Ohmite's thick film resistors can be effectively used as heaters due to their ability to convert electrical energy into heat energy. When an electric current flows through the thick film resistor, electrical resistance causes the current to dissipate energy in the form of heat. The substrate on which the thick film resistor is printed provides thermal stability and helps to evenly distribute heat. It can withstand high temperatures and aids in efficient heat transfer.

The thickness and composition of the resistive layer determine the resistance value and the heating capacity. A thicker layer or one with higher resistivity will produce more heat for a given current. The resistive material is often patterned to control the current path, allowing for uniform heating. The geometry of the pattern can be adjusted to achieve the desired heating profile.

Applications

- Heated Surfaces: Thick film resistors can be used to create heated surfaces by embedding them into or attaching them to various substrates. These are commonly found in applications like heated seats, warming plates, and de-icing systems.

- Precision Heaters: Due to their precise control over temperature and uniform heating capabilities, thick film resistors are used in scientific instruments and laboratory equipment where specific temperature profiles are crucial.

- Industrial Heating: Thick film heater elements are used in industrial applications for heating gases, liquids, or solids. They are particularly useful in situations where compact, reliable heating elements are needed.

Advantages

- Uniform Heating: The design flexibility allows for even distribution of heat across the surface.

- Compact and Lightweight: Thick film heaters are thin and can be integrated into various forms without adding significant bulk.

- Rapid Response: They have fast thermal response times due to the direct conversion of electrical energy to heat at the resistive layer.

- Durability: The ceramic substrate and robust materials used in thick film technology provide longevity and reliability even under harsh conditions.

Custom Wirewound Resistors

Ohmite's entire line of power resistors can be customized to your specific needs, including mounting options, constructions, and more. Request a quote today!

Read More

Custom Thick Film Resistors

Many of Ohmite's thick film products include many customization options. Ohmite's entire line of power resistors can be customized to your specific needs, including mounting options, constructions, and more.

Read More

Custom Ceramic Resistors

Ohmite offers ceramic resistors are compatible with a wide array of end products and are chemically inert and thermally stable. Call now and request a quote today!

Read More

Custom Load Banks

Read More

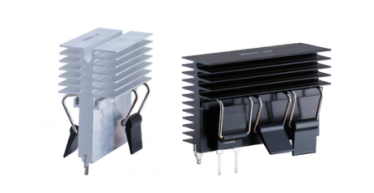

Custom Heatsinks

Ohmite offers heatsinks that include Aluminum Alloy 6063-T5 or equivalent materials and are RoHS-compliant for all your needs. Call now and request a quote today!

Read More

Custom Rheostats

Ohmite Rheostats carry a UL rating with 11 standard sizes allowing many variations and also offers full custom solutions. Call now and request a quote today!

Read More

Customization Options for Standard Parts

Ohmite's catalog contains thousands of individual part numbers, but that isn't all we can do. Ohmite's entire line of resistors, heatsinks can be customized. Call now!

Read More

Ohmite Engineering Team

Ohmite employees a large team of engineers to design and improve our standard and custom resistive and thermal technologies.

Read More

Custom Resistor Assembly

Custom assemblies provide the flexibility of high energy dissipation, while saving space, time and money. Our products can be arranged in several layouts to expand your system functionality.

Read More

Custom Power Resistors

Ohmite has a part series for many applications. High power, high current, high voltage, surge, and current sense are among the most popular. Ohmite's entire line of power resistors can be customized to your specific needs, including mounting options, constructions, and more.

Read More